Working with laser engravers can feel both empowering and slightly intimidating. On one hand, you have a tool that can etch intricate designs into wood, acrylic, leather, and even metal. On the other hand, this same precision machine can cause real harm if safety isn’t taken seriously.

Whether you’re using one in a home studio or managing a busy workshop, safety training is the foundation for both protecting people and ensuring your equipment lasts.

Why Safety Training Matters Right from the Start

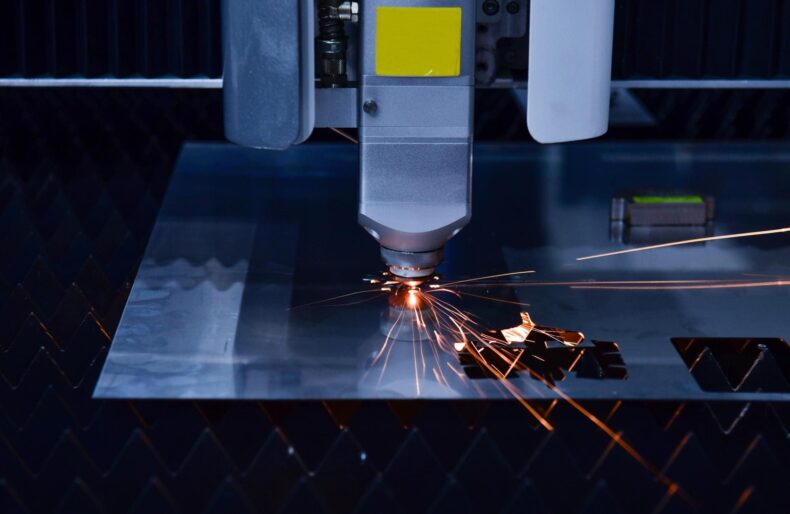

The first thing anyone should understand about laser engraving machines is that they are not toys. They emit powerful beams of concentrated light capable of cutting or vaporizing material.

Without the right precautions, you’re exposed to risks like burns, eye damage, electrical shocks, and even fire hazards. For beginners, this can sound overwhelming, but proper training transforms those fears into confidence. Once you know what to do, safe handling becomes second nature.

Think of safety training not as a one-time lesson, but as an ongoing habit. Technology evolves, new materials enter the market, and each workshop setup has unique risks. Good training programs make you proactive rather than reactive.

The Basics of Laser Engraving Safety

Before we move deeper, let’s ground ourselves in the essentials. Laser engravers typically fall into categories such as CO₂ lasers and fiber lasers. While their applications vary, the safety principles overlap.

One of the most important early lessons is learning how materials react under the beam. Not all surfaces are safe. For instance, engraving PVC releases chlorine gas, which is highly toxic. Wood, acrylic, and coated metals are safer, provided you have ventilation in place.

If you’re still exploring different machines and want to know what options are out there, check resources for laser engravers. They often provide not only machines but also updated safety guidelines tailored to their models.

Personal Protective Equipment Every User Should Have

The workshop rule I repeat most often: if you’re not wearing the right protective gear, you’re not ready to press the power button. Here’s what counts as essential:

- Laser safety glasses: These are not generic goggles. They need to be rated for the specific wavelength of your machine.

- Heat-resistant gloves: Particularly useful if you’re handling materials right after engraving.

- Dust masks or respirators: Engraving produces fine particulates and fumes that should never be inhaled.

- Proper clothing: Avoid synthetic fabrics that can melt. Cotton or specialized workshop attire is safer.

It’s surprising how many accidents stem from something as small as forgetting glasses or working in short sleeves while handling hot material. Safety gear isn’t a suggestion, it’s the uniform of responsibility.

Creating a Workshop Environment That Protects You

Even the best equipment and training won’t protect you if your space is unsafe. Your workshop setup determines whether you can work confidently or end up with constant hazards.

- Ventilation is non-negotiable. Always install an exhaust system or fume extractor. Even “safe” materials can release irritants.

- Fire extinguishers should be within arm’s reach. A laser beam left unattended can ignite material within seconds.

- Electrical safety matters. Plugging a high-powered laser into the wrong outlet can damage both your home wiring and the machine.

- Keep clutter minimal. Loose fabrics, paper scraps, or wood dust near the beam area are invitations for accidents.

Designing your workspace with safety in mind means you’re not relying on luck. You’ve already eliminated half the potential problems before turning the machine on.

Safe Operating Practices You Should Never Skip

Once you’re in your gear and your workspace is set up, operation protocols come next. Many of these are simple, but neglecting them is where most mistakes happen.

- Never leave the machine unattended. Even for “just a minute.”

- Run test cuts. Materials can vary even if they look identical.

- Secure the material. Loose boards or sheets shift and cause misaligned cuts.

- Keep a logbook. Note the settings used for different materials, so you’re not guessing each time.

- Follow the cool-down rule. Wait before touching freshly engraved pieces to avoid burns.

These habits might sound tedious, but in practice they streamline your work and help you avoid costly re-dos or accidents.

Training New Team Members in Workshop Safety

If you run a workshop with more than one operator, structured safety training is critical. It’s not enough to hand someone a manual. Pair new operators with an experienced engraver, and don’t let them handle the machine independently until they can demonstrate safe operation.

Use training sessions to cover both machine-specific protocols and broader workshop rules. Create checklists for daily start-up and shutdown procedures. Encourage questions, and normalize a culture where speaking up about safety concerns is seen as responsible, not bothersome.

Maintenance as Part of Safety Training

Laser engravers require regular maintenance, and skipping this part can directly compromise safety. Dirty lenses scatter beams, faulty cooling systems overheat machines, and clogged exhaust systems release fumes back into your room.

Training should include how to inspect and clean lenses, replace filters, and check alignment. Schedule maintenance as part of the workshop calendar, not as an afterthought. Machines that are cared for not only perform better but also protect their operators.

Common Mistakes Beginners Make and How to Avoid Them

From what I’ve seen, beginners often underestimate how quickly small errors can escalate. Some of the most frequent mistakes include:

- Using unsafe materials without checking toxicity.

- Improvising ventilation with just an open window.

- Skipping protective eyewear because “it’s just a quick job.”

- Failing to test fire extinguishers or not knowing where they’re located.

Avoiding these mistakes comes down to taking every step seriously. Safety isn’t about overreacting, it’s about being prepared so your focus can stay on creativity instead of accidents.

Final Thoughts: Safety as a Creative Enabler

It’s easy to think of safety as a set of limits, but in reality, it’s the opposite. When you know your workshop is secure and your team is trained, you gain freedom. You can take on more ambitious projects without the constant background worry of “what if.”

Laser engraving is one of the most versatile creative tools available today, but its full potential only unfolds when paired with disciplined safety practices. Think of training as an investment not just in your health, but also in your creativity, your equipment’s longevity, and your peace of mind.

If you’re serious about engraving, you should be just as serious about the training that keeps it safe. That’s what turns a risky tool into a reliable partner in your workshop.