Do you know? Cement is responsible for approximately eight percent of artificial carbon dioxide emissions!

Cement is the core material without which we cannot build houses, factories, staircases, bridges, dams, etc.

In the year 2020, an estimated amount of six billion tons of cement was produced worldwide.

Recently, scientists have found an alternative to conventional cement to reduce carbon footprints to a certain extent.

The Conventional Cement

An important building material, Portland cement, is conventional cement made using various raw materials, including limestone, which is burned to form the so-called Clinker.

The process of converting calcium carbonate into calcium oxide releases a lot of carbon dioxide.

With increasing concerns of climate, humans are seeking every possible way to make the circumstances better.

Scientists have been working effortlessly to find an alternative to conventional Portland cement for several years.

The Climate-friendly Alternative

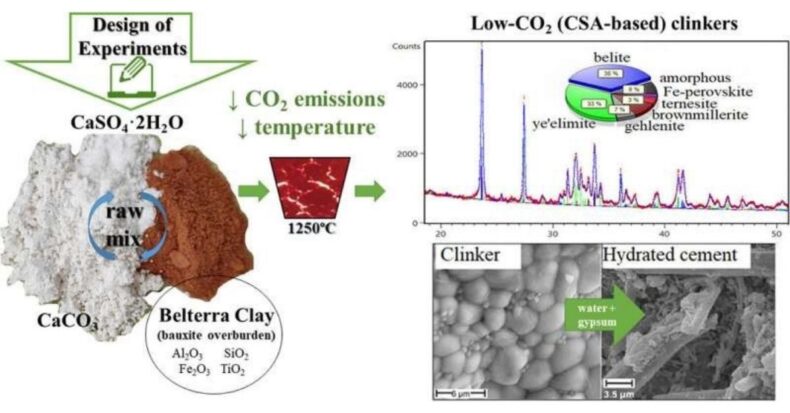

Researchers at the Martin Luther University Halle-Wittenberg (MLU) in Germany and the Brazilian University of Pará have developed an alternative to Portland cement in which they utilized a previously unused raw material.

They found that carbon dioxide emissions during production can be reduced by up to two-thirds.

At first, the researchers replaced a large portion of limestone with bauxite to get the desired result.

However, the primary use of bauxite is aluminum production; thus, it won’t be available in unlimited quantities.

With further research and experimentation, the MLU team and the Brazilian mineralogists found another alternative to the previous choice: an overburdened Belterra Clay.

This clay covers the bauxite deposits in the Tropical regions of the Earth and is nearly 30 meters thick.

Professor Herbert Pöllmann from MLU’s Institute of Geosciences and Geography explains,

“It contains enough minerals with an aluminum content to ensure good quality cement.

It is also available in large quantities and can be produced without additional treatment.”

The Belterra clay can replace only 50-60 percent of the limestone since limestone is the essential raw material in cement production.

Moreover, the burning process to produce this alternative cement require 200 degrees less temperature (i.e., 1,250 °C) as compared to the requirement to produce Portland cement.

This is one more eco-friendly advantage of Belterra clay cement.

“Our methods not only released less carbon dioxide during the chemical conversion but also when heating the rotatory kilns,” says Pöllmann.

In experimental tests, the mineralogists proved that the alternative to conventional cement is entirely stable and meets all the quality standards set on traditional cement.

Further research projects will take place to investigate whether there are also overburden sources in Germany suitable for cement production.

Read More: Scientists discover a 400-year-old gigantic coral on the Great Barrier Reef.