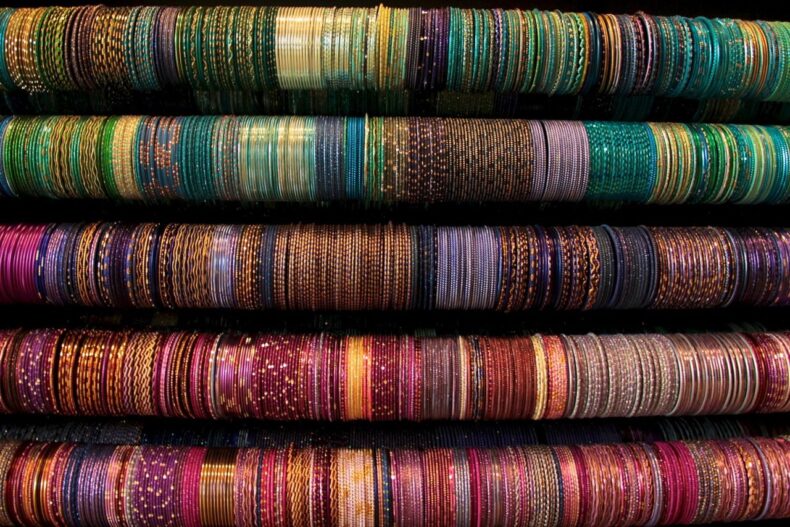

Millions of Indian women wear glass bangles every day, and it is considered part of our culture.

The city of Firozabad is the main producer of glass bangles. And the city is called Suhag Nagri (Suhag means husband in the Hindi language) because glass bangles are considered a sign of matrimonial longevity.

Why does it take around 50 people to make one bangle?

Making glass bangles is a long process, it takes lots of time and effort. It is also considered a dangerous craft. The processes begin with melting the raw material inside a hot blazing furnace.

The silica sand is the main ingredient for making glass bangles. Along with silica scraps of leftover glass pieces like broken bottles or damaged bangles are added to it. Everything is recycled.

The temperature of the furnace was around 2000 Fahrenheit. Women in the factory constantly sweep the broken bangles from the floor. After 10 hours inside the furnace, the glass turns into a runny liquid then color is added to it.

It contains traces of metal, like lead, cadmium, and even mercury, and workers are constantly exposed to those fumes. After that, the melted glass is transferred to the other part of the factory where other workers used to roll the spirals of the bangles.

After all these processes in the factory, each bangle is kept over a flame to melt the edge and bind the glass together. And the last step is to decorate the bangles. At every step, the hard work of every craftsman is included, which makes the craft of making glass bangles more beautiful.

Also Read: Is Indira Gandhi’s fashion still alive?

Firozabad, the city of bangles manufacturing

Firozabad, the city near Agra, is the biggest manufacturer of glass bangles in the world, with a turnover of $150 a year. The whole city is dependent on glass work only, there is no other job or business.

What makes this business risky

After the spiral rolling of bangles, they are steaming hot when they are removed from the rod. This is the toughest part and craftsmen do this without any hand gloves.

When the glass liquid is transferred to the furnace it is very hot and if they are not careful and the glass spills, it will burn the worker. Craftsmen face a high temperature of 2000 Fahrenheit all day long.

This is not it! Craftsmen everyday breathe in the glass dust without any masks. A study shows that 23% of glass bangle workers suffer from chronic bronchitis.

And a piece of glass can damage the worker’s vision and even can blind them. Most of the workers rely on experience to stay safe.

They are offered safety equipment many times but they refuse to use them. The reason is that they are not comfortable with the safety equipment.

How are bangles factories hazardous to the Taj Mahal?

The city of Firozabad is just 30 miles away from Taj. In 2015 when the authorities said the changing color of the Taj Mahal’s white marble to yellow is because of smoke from Firozabad glass factories.

That time was a tough phase for the craftsmen of Firozabad because their livelihood depended on glasswork. But then factories were ordered to use natural gas instead of coal.