Global semiconductor shortage threatens the semiconductor industry. The shortfall has lasted almost a year with no end in sight. U.S.-China tensions over Taiwan and Russia-Ukraine supply chain obstructions have worsened the issue. Multiple industries use semiconductor chips. The shortfall will affect global manufacturing and the economy. IMF’s prognosis of global downturn is noteworthy. The chip crisis could worsen the slowdown.

A semiconductor is a substance that enables electrical conductivity between a conductor and an insulator. Semiconductors are composed of pure components such as silicon or germanium, as well as compounds such as gallium arsenide. Doping can modify the conductivity of metals.

Semiconductors enable electronics to be more compact, less expensive, and powerful. During their original phase, mobile phones weighed roughly 2 pounds, cost around $4,000, and kept a charge for only about 30 minutes of conversation time. Today, however, a person may get a smartphone with a 1-day charge for 5000 rupees.

Source: Industry week

Source: Industry week

Significance of Semiconductors

Ecosystem for technological development: Semiconductors are the building elements of today’s technology, constituting an ecosystem for technological advancement. Semiconductor chips are widely utilised in a variety of applications, including (a) computers and laptops; (b) phones, mobile devices, and other electronic gadgets; (c) automobiles; (d) aviation; (e) medical devices, including diagnostics; and (f) military equipment.ICT infrastructure is driven by these semiconductors (Information and Communication Technologies). Semiconductors and screens are the backbone of today’s electronics, driving the next generation of the digital revolution under Industry 4.0.

Economic security: The epidemic and ensuing lockdowns damaged chip supply to India. Automobile manufacturers such as Mahindra & Mahindra and the Tata group had to reduce output because of the shortage.

Economic development: With deeper integration into the global value chain, the development of the semiconductor and display ecosystem will have a multiplier impact across other sectors of the economy.

Chip manufacturing in the country will help to expand its smartphone assembly sector and boost its electronics supply chain.

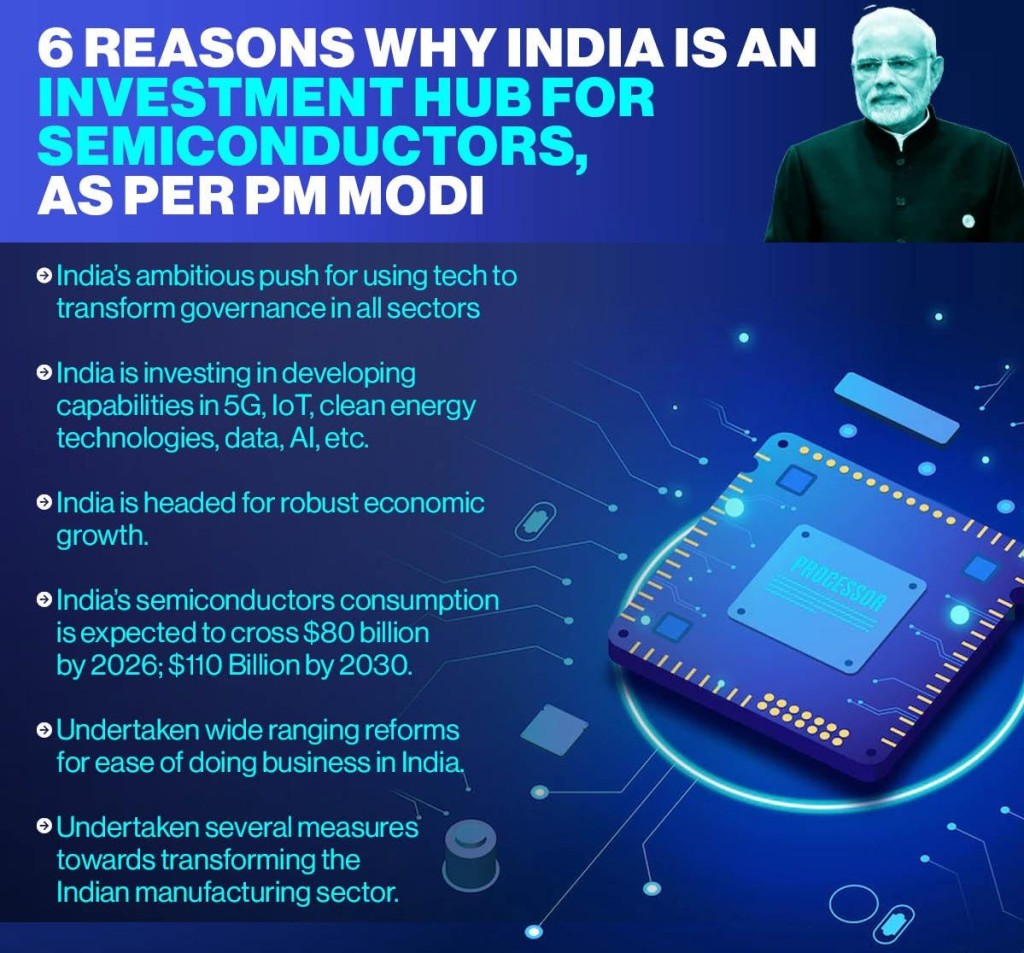

According to the Electronics and Information Technology Ministry, with the rising demand for digital gadgets and electronic items, semiconductor consumption in India would rise to $70-$80 billion by 2026.

In turn, this will provide a wealth of new job prospects for young people in India.

The ability to produce goods domestically would increase tax revenue and export prospects.

Furthermore, India’s import cost would go down since it would need to buy fewer semiconductor chips from abroad.

Geopolitical Benefits:propelled by the rise of big data and the Internet. Increasing domestic production will lessen the country’s dependency on Chinese chip imports, which might prove crucial in times of crisis like the recent conflict in the Galwan Valley.

Enhanced Security: Chips manufactured domestically will be considered “trusted sources,” allowing their incorporation into anything from security cameras to fifth-generation wireless devices. There would be a noticeable rise in the country’s overall cybersecurity reputation if this happened. There are national security issues since they are employed in essential services like communication and electricity transfer.

India’s Future in Semiconductors

As the first significant step in its $20 billion joint venture with Taiwan’s Foxconn, Vedanta Ltd has chosen Gujarat, the home state of Indian Prime Minister Narendra Modi, for its semiconductor project.

The Indian government predicts that the semiconductor business in India would grow from its projected $15 billion in 2020 to an estimated $63 billion in 2026.

While only a few nations, including Taiwan, produce the vast majority of the world’s chips, latecomer India is actively courting businesses to “usher in a whole new age in electronics production” by providing the country with easier access to these technologies.

How important India is to the semiconductor industry

The global value chain is deeply entangled with the interdependence of a select group of countries, including the United States, Taiwan, Japan, China, and a few European countries.

South Korean company Samsung Electronics and Taiwan’s Taiwan Semiconductor Manufacturing Company (TSMC) are the two largest semiconductor producers worldwide.

India excels at semiconductor design and verification. Most semiconductor businesses have R&D in India. Chips, memory, and displays are all imported, 37% from China.

Chip imports might reach $100 billion by 2025, up from $24 billion presently.

India has two fabs: SITAR in Bengaluru and a semiconductor facility in Chandigarh. These make silicon chips for defence and space, not commerce.

Source: Business Today

Source: Business Today

Initiatives taken to promote indigenous Semiconductor capacity

National Policy on Electronics 2019:It hopes to make India a centre for the Electronics System Design and Manufacturing (ESDM) industry. A primary goal is to stimulate innovation in fundamental building blocks like chipsets.Scheme for Promotion of Manufacturing of Electronic Components and Semiconductors (SPECS):The government will subsidise capital expenditures by 25% for a predetermined set of items that make up the electronic goods supply chain. The term “electronic components” encompasses a wide range of items, from simple resistors to complex semiconductors and complex subassemblies.