Modern day outfits are mostly made of polyester fabrics which are not environmentally sustainable since they are derived from petroleum and Polyethylene Terephthalate(PET) are the most common type of plastic which accounts for 82 million metric tons of plastic waste. The textile industry has been considered an evergreen industry for decades. It is surprising to know that the textile industry can solve the above mentioned problems by Ecoline clothing which is the process of manufacturing clothes with Polyesters which are recycled from PET and those recycled Polyesters are known as rPET.

Table of Contents

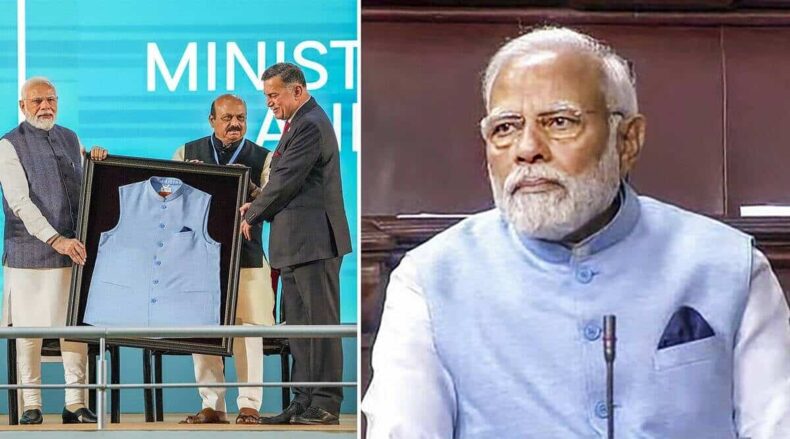

PM WEARS rPET FABRIC:

When Indian Oil Corporation (IOCL) was to initiate its “Unbottled Mission,” they had identified a textile industry called Shree Renga Polymers, which was manufacturing rPET fabrics in Coimbatore, Tamil Nadu. During the launch of the Unbottled initiative, they gifted a special jacket for PM that was made by the industry using rPET, and in the same event, IOCL also distributed uniforms made of rPET. PM Modi has worn that jacket to parliament, and it is considered a sign of support for rPET innovation.

SCALE OF RECYCLING:

The company is said to be recycling nearly 15 lakh PET plastic bottles each day. Of the 50 companies in the region who recycle nearly 3000 tons of plastic bottles per day which could fill the entire football ground! Shree Renga is the only industry which recycles it into a fabric. Even industry giants like Adidas, H&M and Gap Ikea have also taken the initiative to manufacture rPET instead of pure Polyester. They have also increased the scale of recycling by 36% which illustrates the growth of production of rPET fabrics.

WHY NOT COTTON?

Since cotton can produce natural fabric, the preference of cotton over other fabric like rPET which contains recycled plastics can be a big argument. But the production of textiles from cotton is not an environment friendly like most of them think, cotton requires more energy of production compared to rPET which consumes significantly low energy for manufacturing hence helps to reduce carbon footprints. Cotton not only consumes water for its growth but also for in the manufacturing process, it is estimated that 2,700 liters of water is required to manufacture a T-shirt, while the dyeing of cotton fabrics consumes about 5 trillion liters of water worldwide making it non-sustainable while the manufacturing textiles with rPET not even requires a single drop of water.

DOPE DYEING TECHNOLOGY:

The river Noyyal located in Tirupur is the best example for the impact that the dyeing industries could create in the environment. The levels of heavy metals such as Copper, Zinc ,Cadmium and lead are extremely high which ensures that the river is hazardous for anything. rPET could be colored using Dope dyeing technology which colors the fabric while its production itself which the zero water usage or any other wastage which could cause pollution. In this process the fabric is dyed while it is in the semi liquid cellulosic stage. Even Though it has various environmental friendly features like 20% reduction is greenhouse gas emission, it also has business angle since the fabric could maintain the same pigment intensity even after multiple wash.

rPET is one of the marvelous innovations in the field of clothing, it could surely satisfy all the demands that would be put forth by the government to save the environment. So the future of the textile industry clearly lies in recycled polyester fabrics.

ALSO READ: Khadi Brought All the Attention to India at London Fashion Week 23