Altigreen– an automobile company manufacturing electric cargo 3-wheelers have partnered up with Lohum, a company engaged in recycling, and repurposing raw materials of electric vehicles to provide a sustainable way of disposal and recycling of its electric vehicles.

The Government of India published Battery Waste Management rules back in August 2022 in wake of the increasing number of electric vehicles on road. According to the article, it is mandatory for every EV manufacturer to be responsible for their vehicles’ battery waste management.

Every EV manufacturer has an obligation to fulfil the recycling goals set by the central government. In the Rules, the vehicles have been divided on the basis of their usage and wheels. The goals set for 2-wheeler EVs are different from 3-wheeler cargo or 4-wheeler passenger cars.

Altigreen as a 3-wheeler EV maker has taken its first step towards this responsibility and has partnered up with Lohum, which will be responsible for handling Altigreen’s vehicle battery after it has completed its life in the EV.

Specifications of Altigreen and Lohum Partnership

The companies have partnered up with each other where Altigreen will be responsible for providing its vehicle’s batteries that have reached their end-of-life. Lohum will then recycle these batteries and have promised to extract almost 95% of the battery materials that will still be high in purity and can be further used in making new batteries.

Image source: Lohum.com

It is a great concern, as the demand of electric vehicles is on the rise, to manage battery waste in the most efficient manner to reduce pollution caused by irresponsible disposal of batteries after they are no longer usable in the vehicle.

Lohum has currently partnered up with Altigreen for 3 years and seems to have great ambitions in fulfilling a recycler’s responsibility and providing efficient use of resources without getting wasted. They believe they will be able to recycle 1Gwh of batteries from Altigreen’s cargo vehicles in the next 3 years.

Battery Waste Management rules for Electric Vehicles

According to the Battery Waste management rules defined by the government, EV manufacturers will have to submit their reports on their annual plans for the current year and previous year’s information in detail about manufactured batteries, waste batteries collected, recycled/refurbished in Form 1(C) and submitted every year on/before 30th of June.

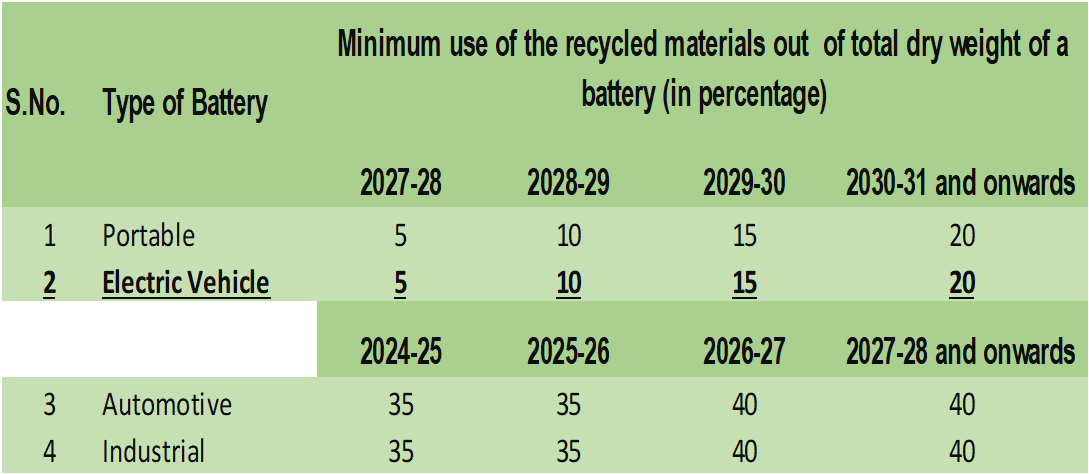

Image source: Mercom India

Lohum as a registered recycler will have an Extended Producer Responsibility certificate which needs to be submitted too as a proof of legal recycler. Any recycler engaged in battery recycling will need this certificate to operate in a legal manner.

It is also mandatory to use a part of the recycled materials in one’s own new vehicles. For Electric Vehicles, battery materials used in the new battery pack should contain 5% recycled materials by the year 2027-28.

This percentage will be increased by 5% every year till 2031, after which new EVs should contain 20% recycled materials in their battery packs every year.

Materials that will be recycled

The Central Pollution Control board (CPCB) has mentioned various materials that have to be extracted from the battery packs that are getting recycled. They are-

1) Lithium

2) Lead

3) Cobalt

4) Nickel

5) Rubber

6) Plastic

7) Glass

8) Others

If the rules published by CPCB are not fulfilled, then the manufacturers and the recyclers will be penalised.

Image source: ET Auto

Amitabh Saran, the CEO of Altigreen Propulsion Labs, expressed his delight over the partnership with Lohum and said that it is another step towards their goal of providing India with a green vehicle that is “Made in India, Made for India”.

Rajat Verma, Founder and CEO of Lohum also showed his support and wished for a more sustainable future with more electric vehicles that are green even in their disposal stage.